Oilseed Hulling

Hulling process must under consideration when oil plants are high in rate of hull, such as sunflower seeds, peanuts and cotton seeds.

After cleaning, the oil bearing seeds are conveyed to the seed hulling machine to remove hulls from the oil seeds for the purpose of obtaining high quality edible oil by the processing of kernels. Oilseed hulling is quite necessary and has a lot of advantages. For example, oilseed hulling can efficiently reduce fibrous content of the meal and increase the marketability as stock feed. As we don’t know, about 99% of oil is stored naturally in kernels and the hulls contain not more than 1% oil. If we don’t remove hulls, they will absorbing or retaining oil in the pressed cake and thus reduce total oil yield. Moreover, processing oilseeds without dehulling reduces the capacity of the oil extraction equipment in addition to more repair and maintenance charges. Besides, wax and coloring matters in hulls always mixed with the pressed oil and you need to refine the oil with extra money to get better edible oil.

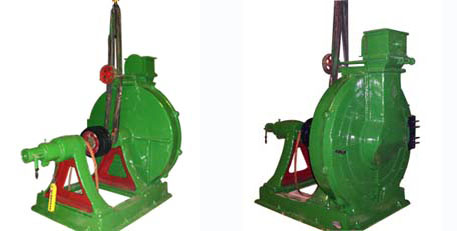

Seed Hulling Machine

Disc huller is one of the widely used seed hulling machines in the process of oilseed hulling.It is used not only in the de-hulling of oilseed shells like cottonseed and peanuts, but also in crushing oilseeds such as soybeans and even the oil cake.

GCBK Series Seed Hulling Machine

GCBK series seed hulling machine is the biggest and the best selling model which are usually used in large oil processing plant. Our machinery’s structure is patented. Through the addition of a stirring wheel between the fixed and moving discs, the working area is increased. This greatly increases the machine’s efficiency and capacity. Despite these productivity-boosting features, our disc huller’s power consumption is only 7.4 kW/t of material.

Main Parameters of the Seed Hulling Machine|

Model

|

Capacity (t/d)

|

Power(kw)

|

Weight (kg)

|

Dimensions(mm)

|

|

GCBK71

|

35

|

18.5

|

1100

|

1820*940*1382

|

|

GCBK91

|

50-60

|

30

|

1700

|

2160*1200*1630

|

|

GCBK127

|

100-170

|

37-45

|

2600

|

2400*1620*1980

|

Welcome to get intouch with us anytime you find interest in our seed hulling machine or complete oil processing plant!