Oil Bleaching

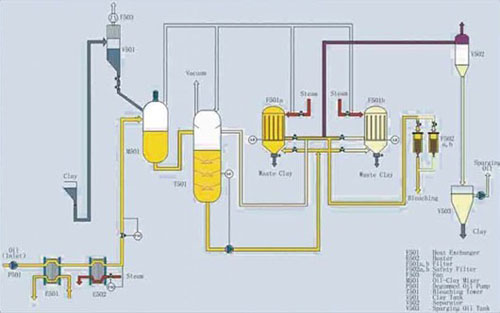

Oil bleaching is carried out before deodorization in an edible oil refinery. The process removes color, as well as residual phosphatides, metals and soaps. To do this, clay is added to the oil then heated, upon which it absorbs pigmentation. Lastly, the oil-clay mixture is filtered and the spent cake is dried to remove the oil.

Oil Bleaching Technology in an Edible Oil Refinery Plant

- Oil and clay is mixed in a vacuum to remove the affects of air and to consume less clay.

- The clay's dosage is dispensed automatically according to the color requirement. A continuous process ensures the clay's even contact with the oil.

- Bleached oil is flushed through closed stainless steel filtration discs for less residue in the meal.

- The filter is controlled automatically to simplify operation and to ensure stable production.

Edible Oil Refinery, Workshop View

Oil Bleaching Flow Chart

Products

Projects

Recent Posts

mini mustard oil mill

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Want to set up a mini mustard oil mill of your own ? With the rapid ...

mustard oil manufacturing process

Mustards are part of the oilseed family and are regarded both as a s...

Mustards are part of the oilseed family and are regarded both as a s...

small size corn oil extraction plant

Interested in begin a small size corn oil extraction plant but dont ...

Interested in begin a small size corn oil extraction plant but dont ...

rice bran oil project

Do you want to make the edible rice bran oil at from using your mill...

Do you want to make the edible rice bran oil at from using your mill...