Solvent Extraction Process

Solvent Extraction is a process which involves extracting oil from oil-bearing materials by treating it with a low boiler solvent as opposed to extracting the oils by mechanical pressing methods, such as expellers, hydraulic presses, etc. The method of solvent extraction process recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.

The method of solvent extraction can be applied directly to any low oil content raw materials. It can also be used to extract pre-pressed oil cakes obtained from high oil content materials. Because of the high percentage of recovered oil, solvent extraction has become the most popular method of extraction of oils and fats. Fat is one of the essential components of the human diet, therefore the demand for oils and fats are increasing with the in-crease in population and standards of living. Today large quantities of oil cakes such as peanut, cottonseed, linseed, kardiseed, neem, castor, mowha, copra, sunflower, etc. are extracted. Direct extraction of rice bran, salseed and soybean is also used.

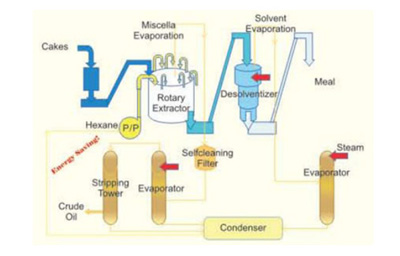

Solvent Extraction Plant Process

The prepared material enters the solvent extractor through the rotary air seal. The extractor consists mainly of a very slow moving articulated band conveyor inside a totally enclosed chamber. The band is lined with perforated sheets and porous stainless steel cloth. The mass of the material moving on this band forms a slow moving bed. During the movement of the bed through the extractor it is washed continuously at various points with miscella of decreasing concentrations and finally with a fresh solvent in a counter current manner by means of sprayers kept in a line over the meal bed. The miscella percolates through the perforated bottom and collects in various hoppers kept below the bed. The miscella from the last hopper, which is concentrated, is taken off for distillation.

Solvent Extraction Plants

In the entire solvent extraction plant, there are some processes that you shoul follow.

1. Preparation of raw material

2. Process of extraction

3. Desolventization of extracted material

4. Distillation of miscella

5. Solvent recovery by absorption

6. Meal finishing and bagging

The normal hexane is highly inflammable, therefore in the entire process which involve high speed machineries such as material preparation, finishing and bagging are carried out at least 50 feet away from the main extraction plant wherein the remaining processing stages involving handling of the solvent are carried out.

Want to set up a mini mustard oil mill of your own ? With the rapid ...

Mustards are part of the oilseed family and are regarded both as a s...

Interested in begin a small size corn oil extraction plant but dont ...

Do you want to make the edible rice bran oil at from using your mill...